INkqubo yeMveliso yokuKhanya kwezinto zokomisa

INkqubo yeMveliso yokuKhanya kwezinto zokomisa

Intshayelelo yeNkqubo

Kwiminyaka yakutshanje, ngokunyuka kwemithombo yokusingqongileyo, ukusetyenziswa ngokupheleleyo kwamandla e-biomass kuye kwabaluleke ngakumbi nangakumbi kuthi.Ngenxa yokufuma okuphezulu kwe-sawdust, iinkuni ezaphukileyo, ezikhokelela ekutshisweni okungaphelelanga, okukhokelela ekubeni i-spark itshise isikhwama sothuli ngasemva kwesityalo esomileyo, esingabangeli kuphela ukukhutshwa okugqithisileyo, kodwa kunye neendleko eziphezulu. ukutshintsha ibhegi yothuli.Kwinkqubo yokuvelisa iimveliso zokhuni kunye namafutha e-biomass anexabiso eliphezulu lokutshisa okutshisayo, iinkuni zokhuni kunye ne-dregs ephukile zifunekayo ukwenza inkqubo yokomisa.

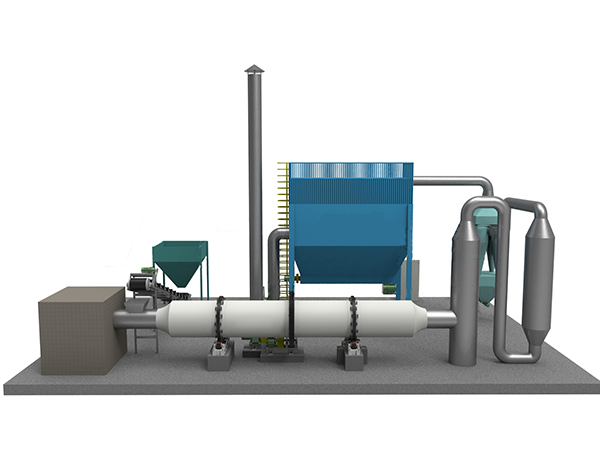

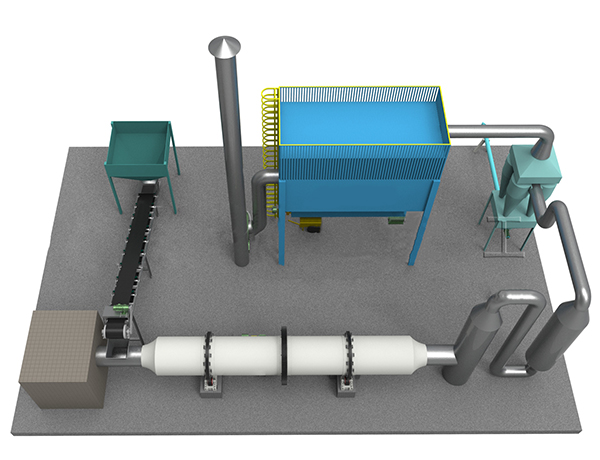

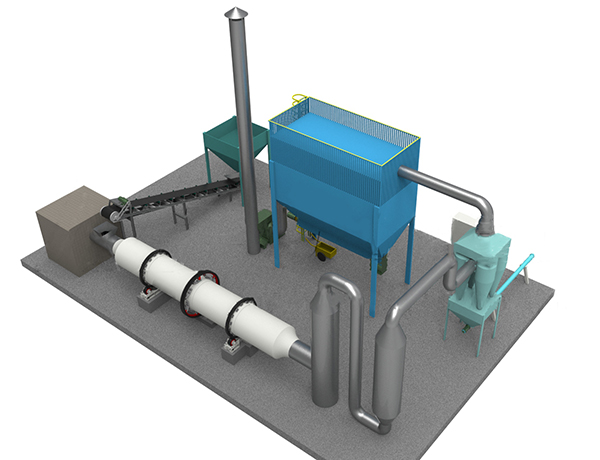

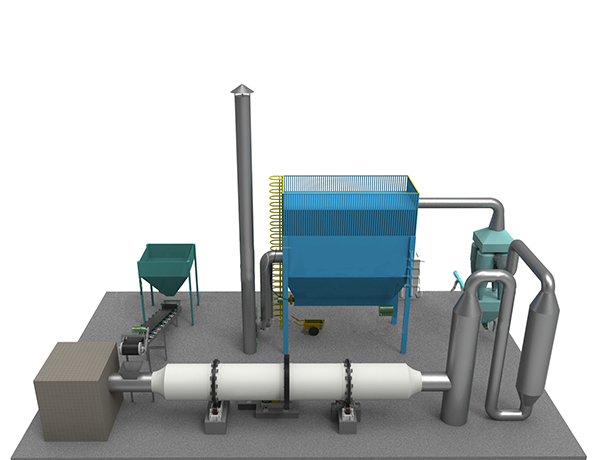

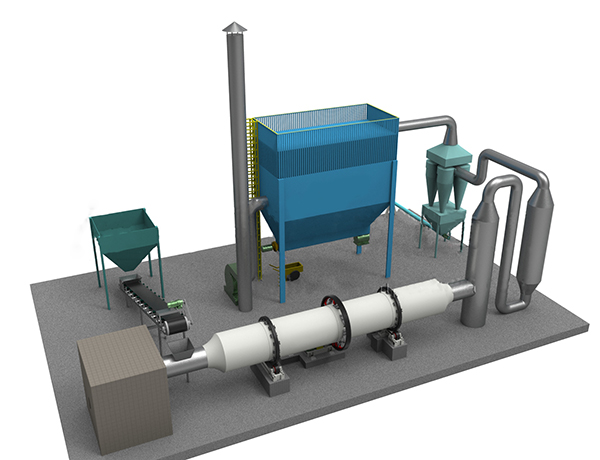

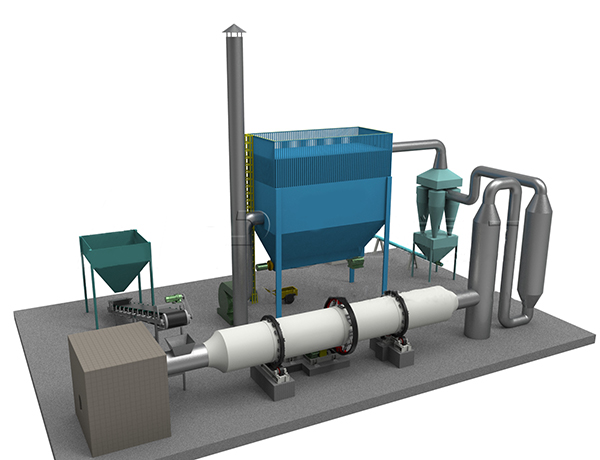

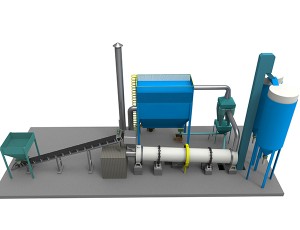

Inkqubo Flow

Emva kokutyiswa kwi-hopper, phantsi komsebenzi womxhuzulane, i-gravity iya kuwela kwibhanti lokuhambisa elibekwe ngaphantsi kwe-hopper, kwaye emva koko iya kuhanjiswa kumatshini wokuhlola, ubukhulu, umcu kunye nezinye izinto ezingaqhelekanga ziya kuba. yahlulwe ngaphandle emva kokuhlolwa, kwaye amaqhekeza afanayo aya kuhanjiswa ekupheleni kokutya kwesomisi (I-cylinder enye okanye i-cylinder dryer emithathu iya kukhethwa ngokwemeko yenkonzo) ngumqhubi webhanti phantsi komatshini wokuhlola.Isiphelo sokutya kwesomisi sidityaniswe nomthombo wobushushu kwaye isiphelo sokukhupha sidityaniswe nemibhobho yomoya wepulse.Udonga lomlilo luya kumiswa kwisitovu sokuqhuma okutshisayo ukwenzela ukuba kuqinisekiswe ukhuseleko lwenkqubo yokomisa, ukuphelisa isiganeko sokutsha kwezinto kwi-dryer, kunye nobushushu obudlula kumbhobho buya kufakwa phakathi kwesitovu esitshisayo kunye nesitofu. isomisi njengecandelo lesithinteli sobushushu.Izinto ziya kuziswa kumbhobho we-pulse oguquliweyo emva kokuba womisiwe kunye nokuphelelwa ngamanzi emzimbeni okokuqala ngaphakathi kwesomisi, eya kuba kwifom ebilayo emisiweyo kububanzi obukhulu bombhobho we-pulse, kwaye emva koko iya komiswa ngokukhawuleza. emva kokudibana nomoya wobushushu ophelileyo ovela kwisomisi.Kwaye izinto eziphathekayo ziya kugxothwa kumbhobho we-pulse ngemimoya eqinile kwaye zihanjiswe kwinqanaba lokuqala lomqokeleli we-cyclone xa umxholo wamanzi ufikelela kwimfuno yoyilo, kwaye i-80% yezinto ezomileyo ziya kuqokelelwa, kwaye emva koko ungene kwinqanaba lesibini lomqokeleli we-cyclone. emva kokudlula kwidrafti yedrafti yokuqokelela izinto ezisekhohlo.Umqokeleli wenqanaba lesibini le-cyclone unokutshintshwa yingxowa yohlobo lomqokeleli wothuli.

Izinto eziluncedo kwiNkqubo

Amandla omisa kakhulu kunye nexesha elifutshane lokumisa

Inkqubo yokomisa izinto ezikhanyayo ine-design ephezulu, evumela ukuba izinto zibe noqhagamshelwano olupheleleyo kwi-dryer, indawo egcweleyo yeengqungquthela yindawo yokomisa esebenzayo, kwaye inamandla okumisa okunzulu.Ngesomisi sokuhamba komoya we-pulse, ixesha lokumisa lisiqingatha kuphela sesomisi esiqhelekileyo, ukusebenza kakuhle komatshini wokomisa kwanda kakhulu.

Ixabiso eliphantsi lokumisa kunye nokusebenza kakuhle kokumisa

Inkqubo yokomisa izinto ezikhanyayo inesakhiwo esiphambili, esinendawo encinci egqunyiweyo ye-mall, kulula ukwakha kunye nokwenza ulondolozo.Ukusebenza kakuhle kwe-thermal kunokufikelela kwi-90% xa yomisa amanzi angenayo.

Isiphumo esihle sokumisa kunye nenqanaba eliphezulu lokuzenzekelayo

Ukufuma kokugqibela kuzinzile (10% -13%) emva kokuba izinto zokukhanya eziqhelekileyo zomiswe, kwaye izinto ezomileyo aziqukethe ukungcola.Isitofu esitshisayo sinokuthi sihambelane ne-alamu yeqondo lokushisa eliphezulu, isixhobo sokubeka iliso lomlilo, i-alamu yokutshisa, isixhobo sokuhlukanisa i-fuel, esinokuqinisekisa ukhuseleko lokutsha.

Iiparamitha zobuGcisa

| Umzekelo | Idayamitha yesilinda(mm) | Ubude besilinda(mm) | Umthamo wesilinda(m3) | Isantya se-Cylinder rotary (r/min) | Amandla(kW) | Ubunzima(t) |

| VS0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

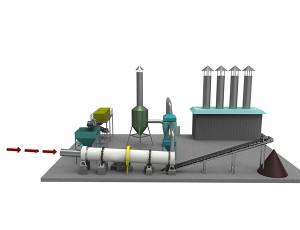

Iifoto zeNdawo eziSebenzayo