UkuSetyenziswa okuBanzi kweNkunkuma yeNkqubo yokomisa ubushushu

UkuSetyenziswa okuBanzi kweNkunkuma yeNkqubo yokomisa ubushushu

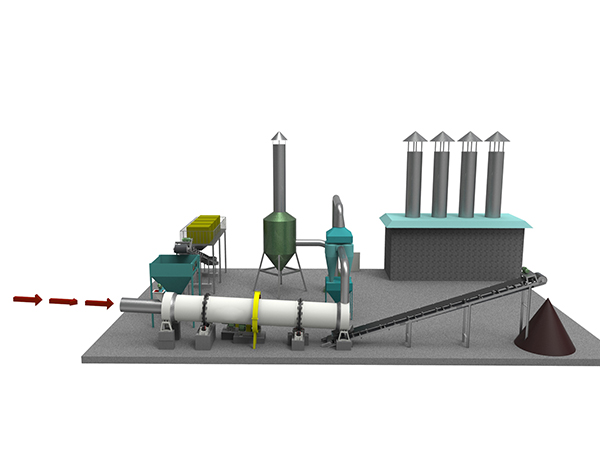

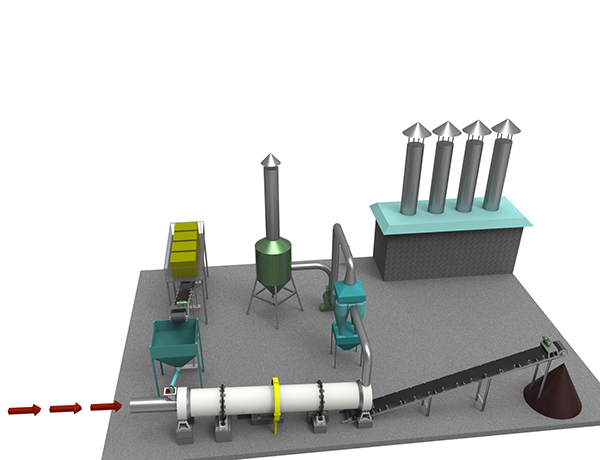

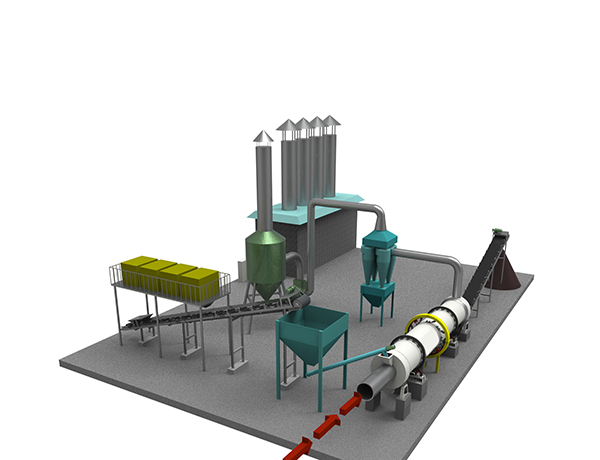

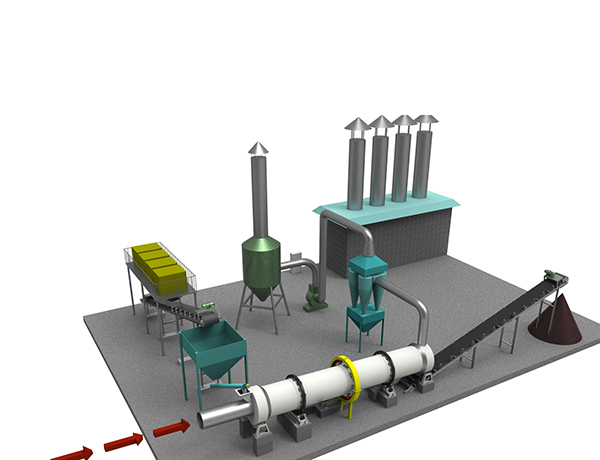

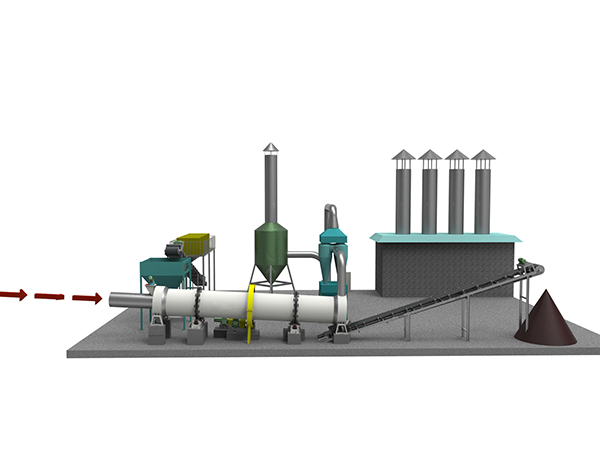

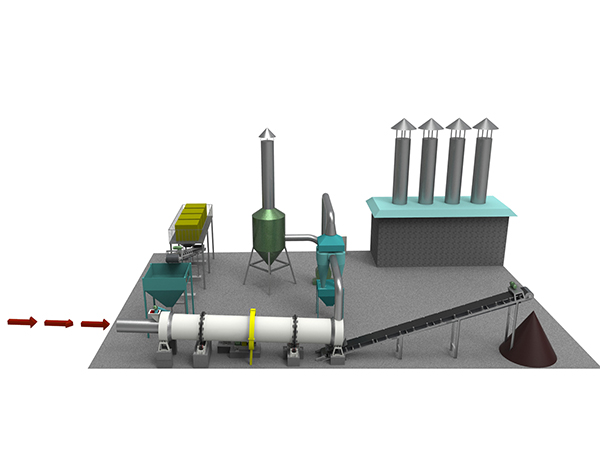

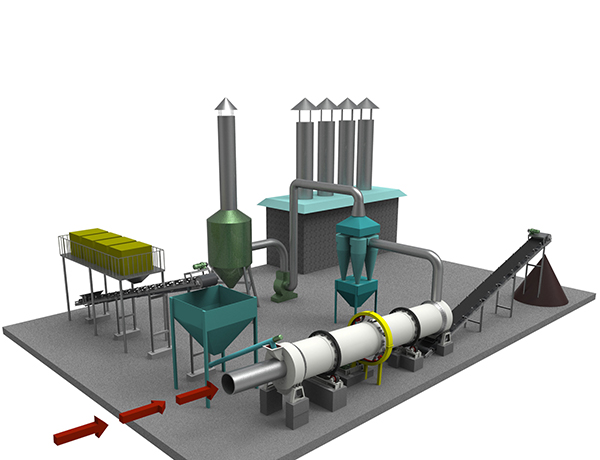

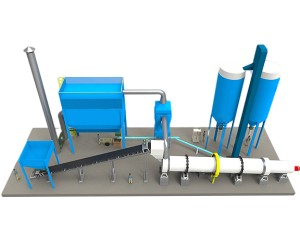

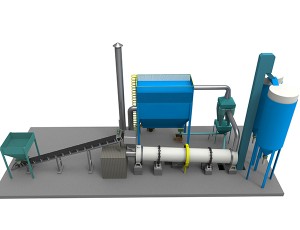

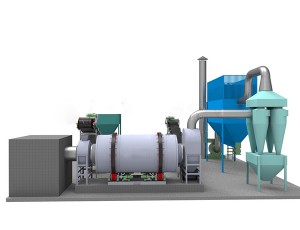

Inkqubo Flow

Iskimu sokwandisa ukusetyenziswa kwamandla ashushu esixokelelwano sinokuyilwa ngokwezinto ezahlukeneyo, inkunkuma yobushushu kunye nokuhamba kobushushu.

Amatyala 1: 200T/D iProjekthi yokuLungisa iSludge enye yeeNkampani zeDalian Petrochemical, kunye nokuphuma kwamanzi: 750000 Nm³/h;ubushushu bokukhupha: 135 ℃;Uyilo lwethu kukusebenzisa iiseti ezintathu ze-VS 4 x 32m dryer, ezithe zafakwa kwimveliso.

Case 2: 4T/D iProjekthi yokuLungisa i-Sludge kwenye yeefektri zokudaya zase-Shanghai, ukuhamba kwe-exhaust: 10000Nm³/h, ubushushu bokukhupha:180℃;Uyilo lwethu kukusebenzisa i-VS 2 x 5m isomisi esiphakathi, esifakwe kwimveliso.

Izinto eziluncedo kwiNkqubo

1. Ukusetyenziswa kobushushu, ukonga amandla kunye nokukhuselwa kwendalo;

2. Akukho kusetyenziswa kwamafutha, ukusetyenziswa kwamandla ambalwa, inkqubo yokususa uthuli yokuqala ingasetyenziselwa ukugcina utyalo-mali;

3. Fumana imathiriyeli ekrwada ekuhlaleni, umhlaba owongezelelweyo awufuneki;

4. Inqanaba eliphezulu lokuzenzela, ukonga abasebenzi;

5. Ixesha lokumisa linokulungiswa, kwaye umxholo wamanzi unokulawulwa emva kokumisa.

Iiparamitha zobuGcisa

| Umzekelo | Idayamitha yesilinda(mm) | Ubude besilinda(mm) | Umthamo wesilinda(m3) | Isantya se-Cylinder rotary (r/min) | Amandla(kW) | Ubunzima(t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 14 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |