Comprehensive Utilization of Waste Heat Drying System

Comprehensive Utilization of Waste Heat Drying System

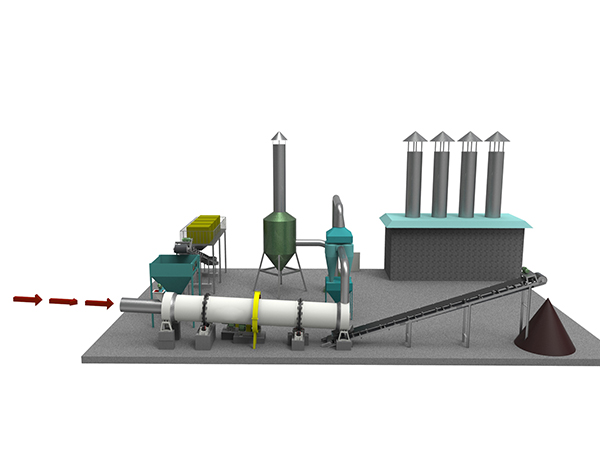

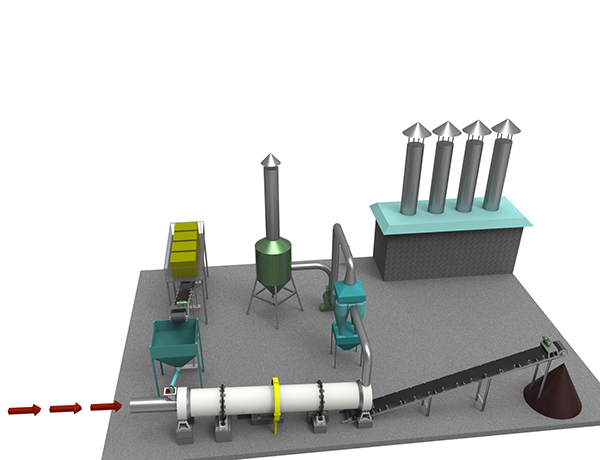

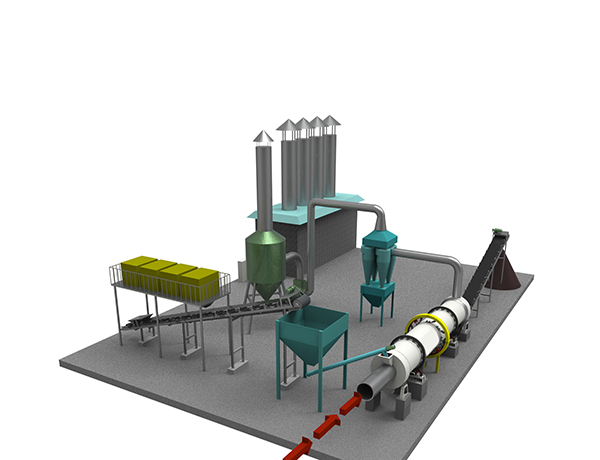

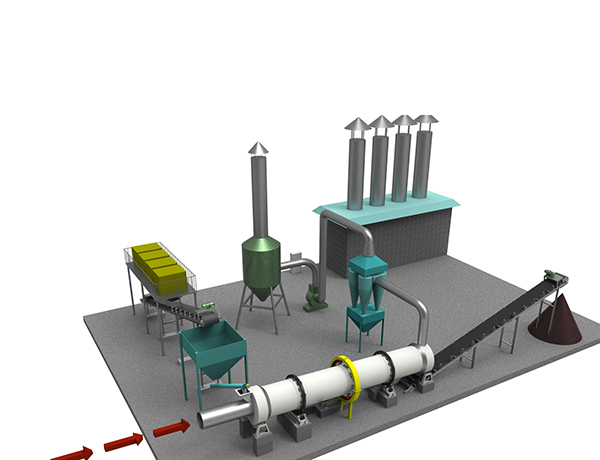

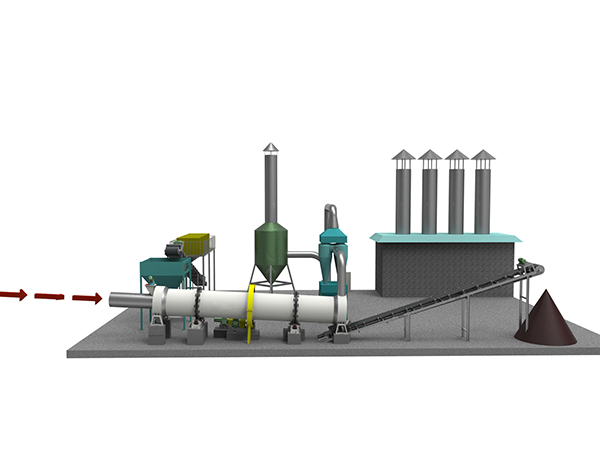

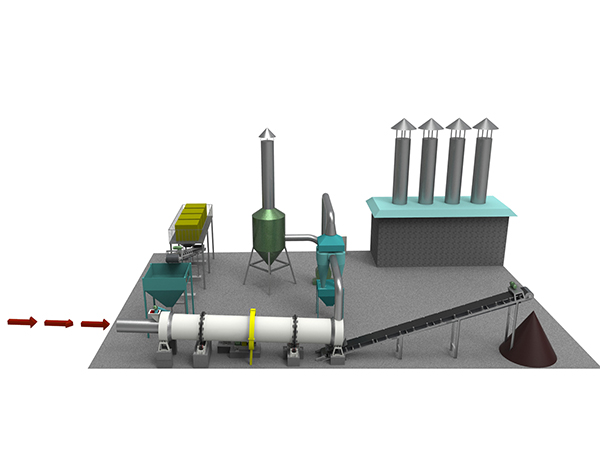

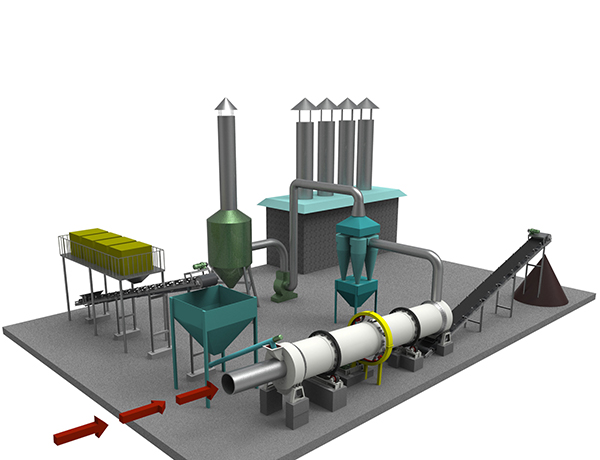

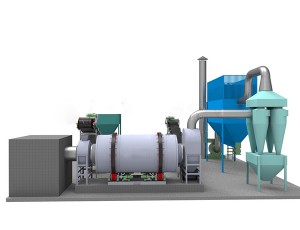

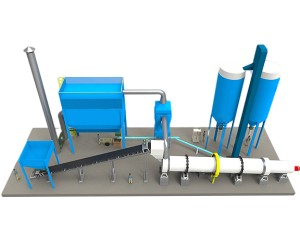

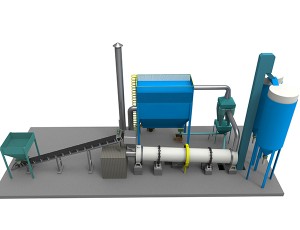

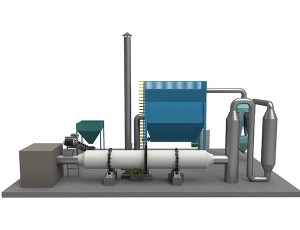

Process Flow

The scheme for maximizing the utilization of system thermal energy can be designed as per different material, waste heat temperature and waste heat flow.

Cases 1: 200T/D Sludge Processing Project for one of Dalian Petrochemical Companies, and exhaust flow: 750000 Nm³/h; exhaust temperature: 135℃; Our design is to use three sets of VS 4 x 32m dryer, which have been put into production.

Case 2: 4T/D Sludge Processing Project for one of Shanghai dyeing factories, exhaust flow: 10000Nm³/h, exhaust temperature:180℃; Our design is to use VS 2 x 5m intermittent dryer, which has been put into production.

System Advantages

1. Waste heat utilization, energy saving and environmental protection;

2. No fuel consumption, few power consumptions, the original dust removal system can be used to save investment;

3. Obtain raw material locally, additional land is not required;

4. High level of automation, laborsaving;

5. Drying time can be adjusted, and the water content can be controlled after drying.

Technical Parameters

|

Model |

Cylinder diameter(mm) |

Cylinder length(mm) |

Cylinder volume(m3) |

Cylinder rotary speed (r/min) |

Power(kW) |

Weight(t) |

|

VS 0.6x5.8 |

600 |

5800 |

1.7 |

1-8 |

3 |

2.9 |

|

VS 0.8x8 |

800 |

8000 |

4 |

1-8 |

4 |

3.5 |

|

VS 1x10 |

1000 |

10000 |

7.9 |

1-8 |

5.5 |

6.8 |

|

VS 1.2x5.8 |

1200 |

5800 |

6.8 |

1-6 |

5.5 |

6.7 |

|

VS 1.2x8 |

1200 |

8000 |

9 |

1-6 |

5.5 |

8.5 |

|

VS 1.2x10 |

1200 |

10000 |

11 |

1-6 |

7.5 |

10.7 |

|

VS 1.2x11.8 |

1200 |

11800 |

13 |

1-6 |

7.5 |

12.3 |

|

VS 1.5x8 |

1500 |

8000 |

14 |

1-5 |

11 |

14.8 |

|

VS 1.5x10 |

1500 |

10000 |

17.7 |

1-5 |

11 |

16 |

|

VS 1.5x11.8 |

1500 |

11800 |

21 |

1-5 |

15 |

17.5 |

|

VS 1.5x15 |

1500 |

15000 |

26.5 |

1-5 |

15 |

19.2 |

|

VS 1.8x10 |

1800 |

10000 |

25.5 |

1-5 |

15 |

18.1 |

|

VS 1.8x11.8 |

1800 |

11800 |

30 |

1-5 |

18.5 |

20.7 |

|

VS 1.8x15 |

1800 |

15000 |

38 |

1-5 |

18.5 |

26.3 |

|

VS 1.8x18 |

1800 |

18000 |

45.8 |

1-5 |

22 |

31.2 |

|

VS 2x11.8 |

2000 |

11800 |

37 |

1-4 |

18.5 |

28.2 |

|

VS 2x15 |

2000 |

15000 |

47 |

1-4 |

22 |

33.2 |

|

VS 2x18 |

2000 |

18000 |

56.5 |

1-4 |

22 |

39.7 |

|

VS 2x20 |

2000 |

20000 |

62.8 |

1-4 |

22 |

44.9 |

|

VS 2.2x11.8 |

2200 |

11800 |

44.8 |

1-4 |

22 |

30.5 |

|

VS 2.2x15 |

2200 |

15000 |

53 |

1-4 |

30 |

36.2 |

|

VS 2.2x18 |

2200 |

18000 |

68 |

1-4 |

30 |

43.3 |

|

VS 2.2x20 |

2200 |

20000 |

76 |

1-4 |

30 |

48.8 |

|

VS 2.4x15 |

2400 |

15000 |

68 |

1-4 |

30 |

43.7 |

|

VS 2.4x18 |

2400 |

18000 |

81 |

1-4 |

37 |

53 |

|

VS 2.4x20 |

2400 |

20000 |

91 |

1-4 |

37 |

60.5 |

|

VS 2.4x23.6 |

2400 |

23600 |

109 |

1-4 |

45 |

69.8 |

|

VS 2.8x18 |

2800 |

18000 |

111 |

1-3 |

45 |

62 |

|

VS 2.8x20 |

2800 |

20000 |

123 |

1-3 |

55 |

65 |

|

VS 2.8x23.6 |

2800 |

23600 |

148 |

1-3 |

55 |

70 |

|

VS 2.8x28 |

2800 |

28000 |

172 |

1-3 |

75 |

75 |

|

VS 3x20 |

3000 |

20000 |

14 |

1-3 |

55 |

75 |

|

VS 3x23.6 |

3000 |

23600 |

170 |

1-3 |

75 |

85 |

|

VS 3x28 |

3000 |

28000 |

198 |

1-3 |

90 |

91 |

|

VS 3.2x23.6 |

3200 |

23600 |

193 |

1-3 |

90 |

112 |

|

VS 3.2x32 |

3200 |

32000 |

257 |

1-3 |

110 |

129 |

|

VS 3.6x36 |

3600 |

36000 |

366 |

1-3 |

132 |

164 |

|

VS 3.8x36 |

3800 |

36000 |

408 |

1-3 |

160 |

187 |

|

VS 4x36 |

4000 |

36000 |

452 |

1-3 |

160 |

195 |