Ka Faa'iidaysiga Dhamaystiran ee Nidaamka Qalajinta Kulaylka Qashinka

Ka Faa'iidaysiga Dhamaystiran ee Nidaamka Qalajinta Kulaylka Qashinka

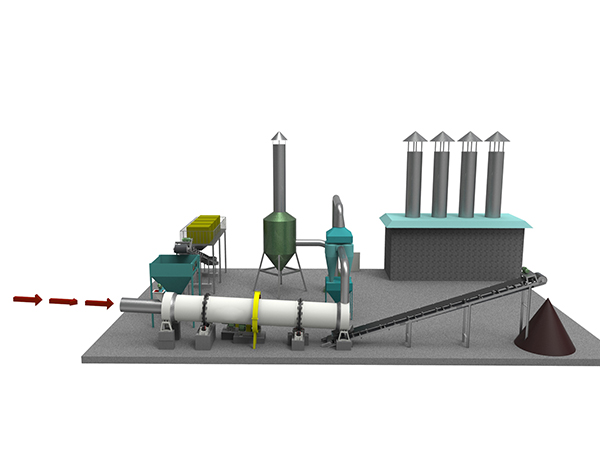

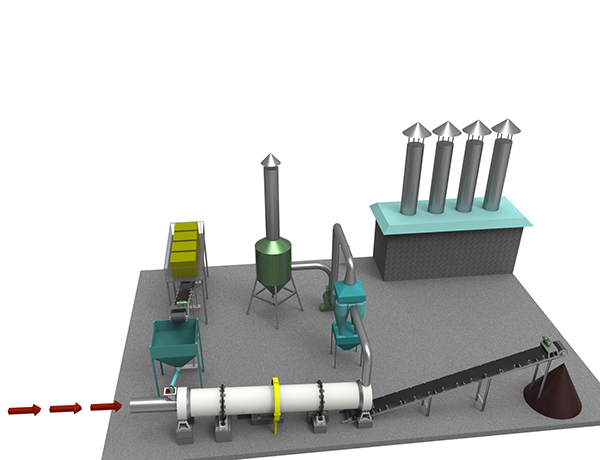

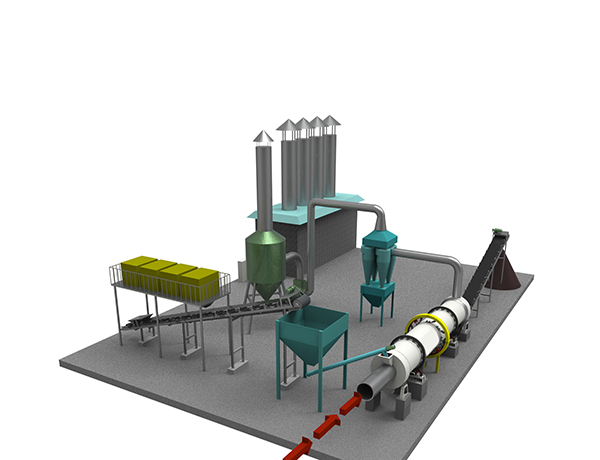

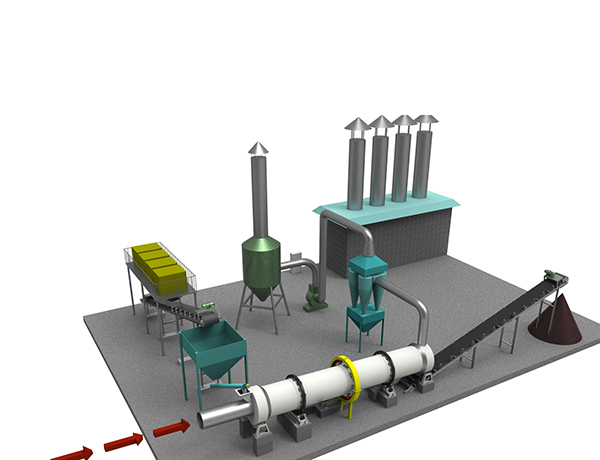

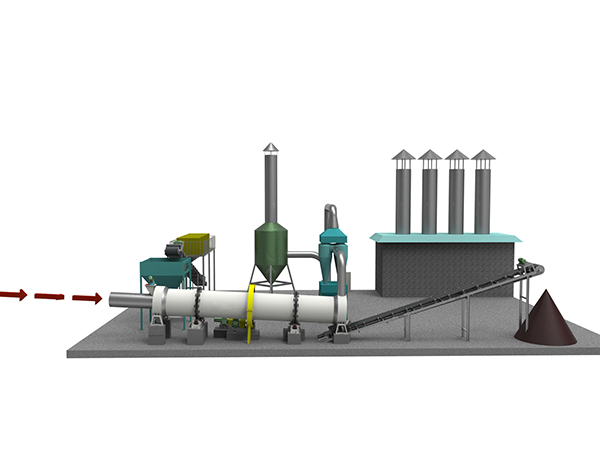

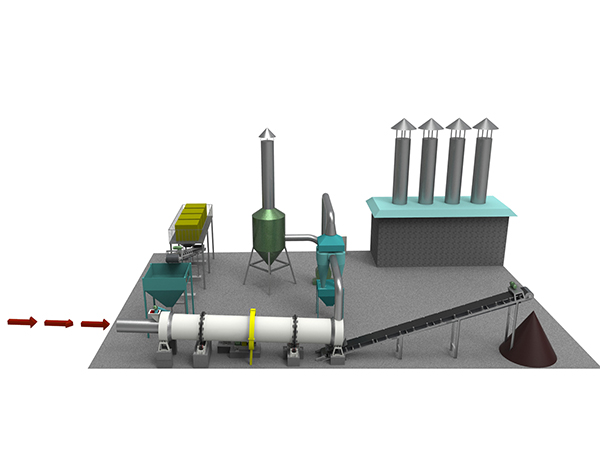

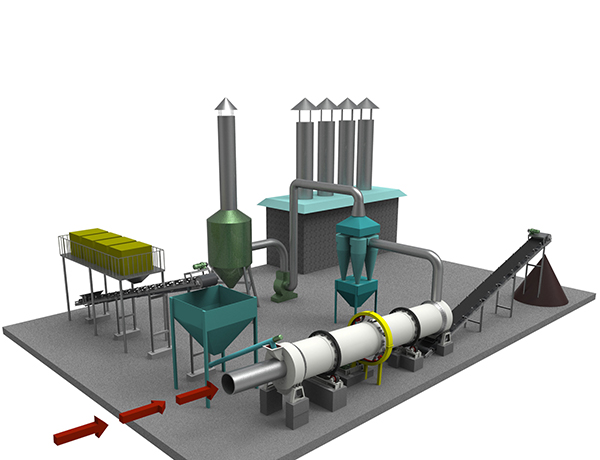

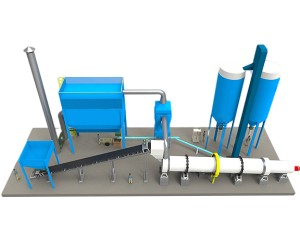

Socodka Geedi socodka

Qorshaha kor loogu qaadayo ka faa'iidaysiga tamarta kulaylka nidaamka waxaa loo qaabayn karaa sida walxaha kala duwan, heerkulka kulaylka qashinka iyo socodka kulaylka qashinka.

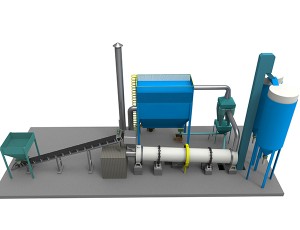

Kiisaska 1: 200T/D Mashruuca Habaynta Walaxda ee mid ka mid ah Shirkadaha Dalian Petrochemical, iyo socodka qiiqa: 750000 Nm³/h;heerkulka qiiqa: 135 ℃;Naqshadayntayadu waa in la isticmaalo saddex qaybood oo ah VS 4 x 32m qalajiyaha, kuwaas oo la geliyay wax soo saarka.

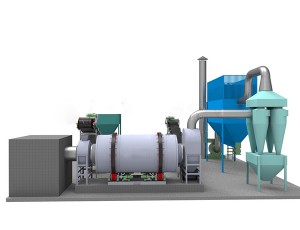

Kiiska 2: 4T/D Mashruuca Hagaajinta Xabagta ee mid ka mid ah warshadaha dheeha Shanghai, socodka qiiqa: 10000Nm³ / h, heerkulka qiiqa: 180 ℃;Naqshadayntayadu waa in la isticmaalo VS 2 x 5m qalajiyaha dhexdhexaadka ah, kaas oo la geliyay wax soo saarka.

Faa'iidooyinka nidaamka

1. Isticmaalka qashinka qashinka, badbaadinta tamarta iyo ilaalinta deegaanka;

2. Shidaal la'aan, isticmaalka tamarta yar, nidaamka ka saarista boodhka asalka ah ayaa loo isticmaali karaa si loo badbaadiyo maalgashiga;

3. Helitaanka alaabta ceeriin gudaha, dhul dheeraad ah looma baahna;

4. Heerka sare ee otomaatiga, badbaadinta shaqada;

5. Waqtiga qallajinta waa la hagaajin karaa, iyo waxa ku jira biyaha waa la xakameyn karaa ka dib marka la qalajiyo.

Qiyaasaha Farsamada

| Qaabka | Dhexroor dhululubo (mm) | Dhererka dhululubo (mm) | Mugga dhululubo (m3) | Xawaaraha dhululubo (r/min) | Awood (kW) | Miisaanka (t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 14 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |