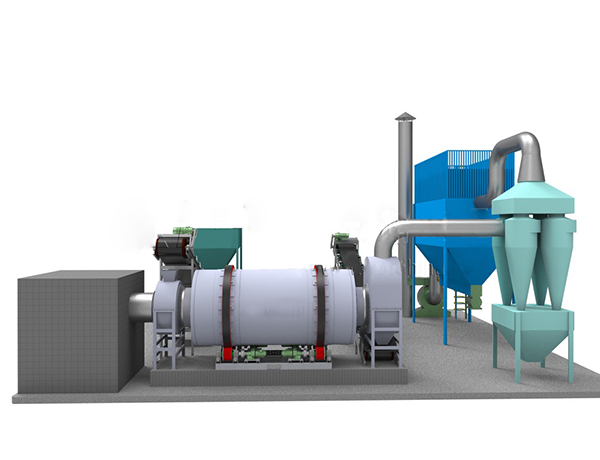

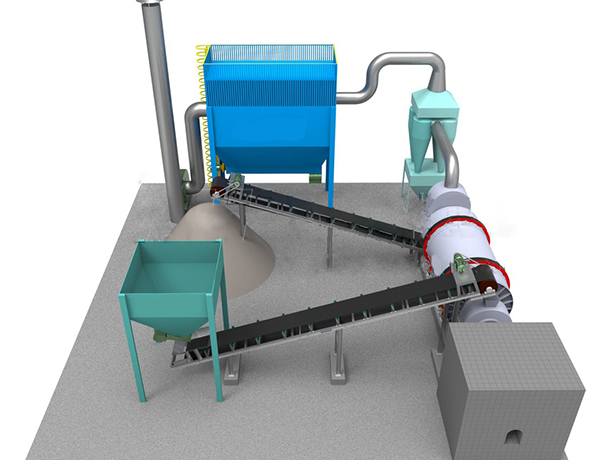

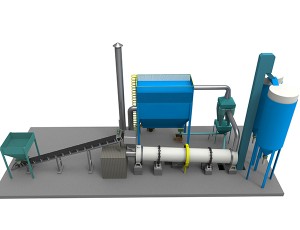

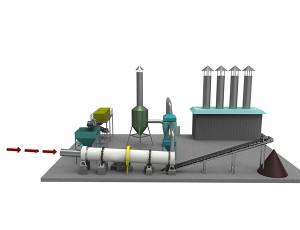

Nidaamka Qalajinta Qalabka Granular

Nidaamka Qalajinta Qalabka Granular

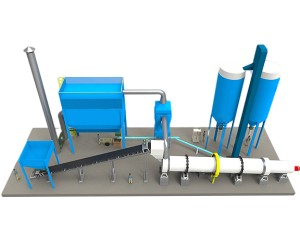

Faa'iidooyinka nidaamka

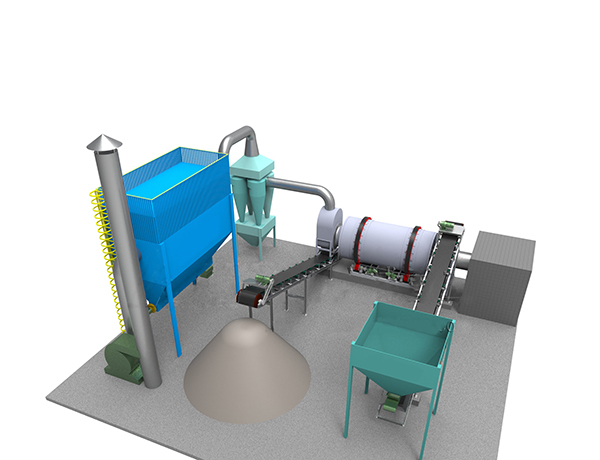

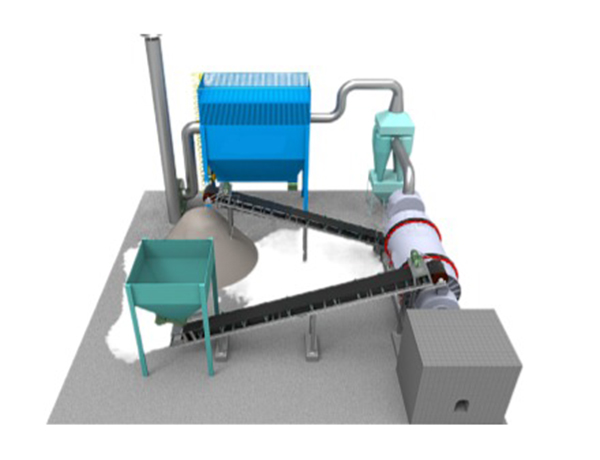

Hufnaanta kulaylka sare

Qalabka ilaalinta kulaylka leh caabbinta kulaylka sare, oo ay weheliso muuqaalka isticmaalka kulaylka ee qalajiyaha saddex-dhululubo, saamaynta tamarta tamarta ayaa muuqata.

Maalgelinta qalabka hooseeya

Heerkulka walxaha waa <50 ℃, kaas oo si toos ah loo geli karo bakhaarka alaabta, iyo qalabka qaboojinta looma baahna;Heerkulka gaaska dabada waa hooseeyaa, qalabka ka saarista siigada ayaa leh nolol adeeg dheer.

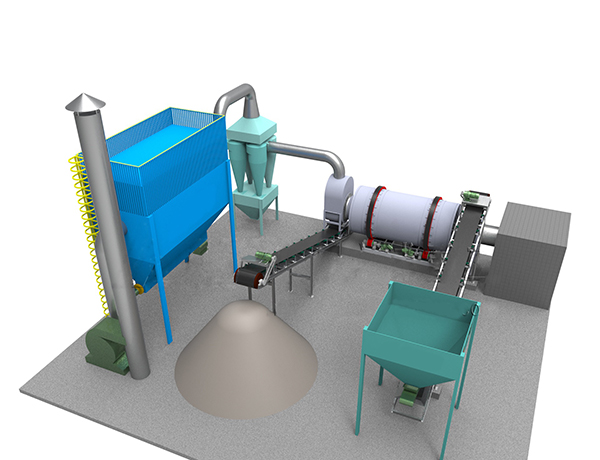

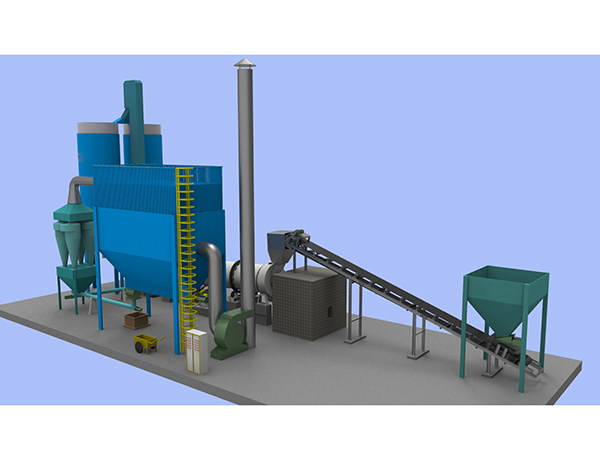

Meel yar oo dhulka ah, fududahay in la rakibo

Meesha ay ku daboolan tahay waa 50% ka yar kan qalajiyaha hal dhululubada ah, maalgashiga dhismaha ayaa hoos u dhacay 50% isticmaalka korantada waxaa la dhimay 60%, qaabeynta nidaamka qalajinta waa mid isku dhafan oo leh socodka habka fudud.

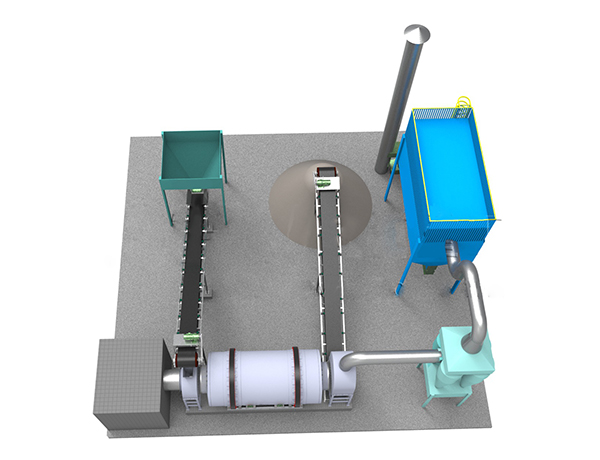

Mabda'a Shaqada

Alaabta waxaa lagu quudiyaa foornada in kastoo dhamaadka foornada (dhinaca sare ee dhululubada).Sababtoo ah dhululubada ayaa u janjeerta oo si tartiib ah u wareegta, alaabtu waxay la socotaa goobada iyo sidoo kale jihada axial (laga bilaabo dhinaca sare ilaa dhinaca hoose).Ka dib marka la maro isbeddel jidheed iyo kiimiko, walxuhu waxay galaan mashiinka qaboojinta iyada oo loo marayo daboolka madaxa ee foornada ka dib marka la dhammeeyo calcinta.Shidaalka waxaa lagu shubaa madaxa foornada iyada oo loo sii marayo madaxa foornada, gaaska qiiqa ayaa soo daadan doona dhammaadka foornada ka dib marka lagu beddelo kulaylka alaab.

Halbeegyada Farsamo ee Saddexda Dabaqle ee Qalajiyaha

| Qaabka | Xogta silinder | Awood (t/h) | Xawaaraha dhululubo (r/min) | Awood (kW) | ||||

| Dhexroor dhululubo dibadda ah (m) | Dhererka dhululubada dibadda (m) | Mugga dhululubo (m3) | Webiga ciid | Dambaska duula | Slag | |||

| VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2×4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3×2 |

| VS2×5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4×2 |

| VS2×6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7.5×2 |

| VS2.2×4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5.5×2 |

| VS2.5×6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5.5×4 |

| VS2.7×7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7.5×4 |

| VS2.8×6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5.5×4 |

| VS3×6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7.5×4 |

| VS3×7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7.5×4 |

| VS3.2×7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11×4 |

| VS3.2×8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11×4 |

| VS3.6×8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15×4 |

| VS3.8×9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15×4 |

| VS4×10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18.5×4 |

| VS4.2×8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18.5×4 |

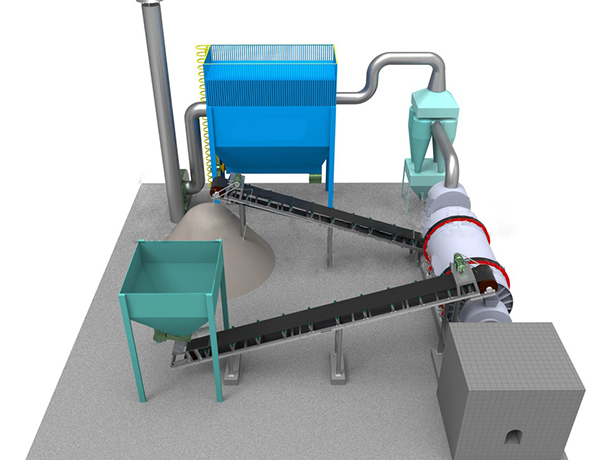

Alaabta la qalajiyey