Kiln Rotary ee Warshada Soosaarka Sibidhka

Kiln Rotary ee Warshada Soosaarka Sibidhka

Hordhac

Kilinka sibidhka waxaa inta badan loo isticmaalaa xisaabinta clinker waxayna leedahay nooc qalalan iyo nooc qoyan.

Qalabka Metullurgical iyo kiimikaad waxaa inta badan loo isticmaalaa caleenta birta birta ee liidata, caleenta oksidaynta ee chromium ore, ferronickel ore;Calcination of aluminium bauxite macdanta sare ee warshadda walxaha refractory iyo aluminium hydroxide, clinker, caleenta aluminium hydroxide calcination ee warshadda aluminium;Calcination of chrome ore iyo budada chrome ee warshad kiimikaad, iwm.

Kiln-ka lime ee firfircoon waxa loo isticmaalaa kasbashada lime-firfircoon iyo dolomite ee warshadda samaynta birta iyo warshadda daawaha birta.

Mabda'a Shaqada

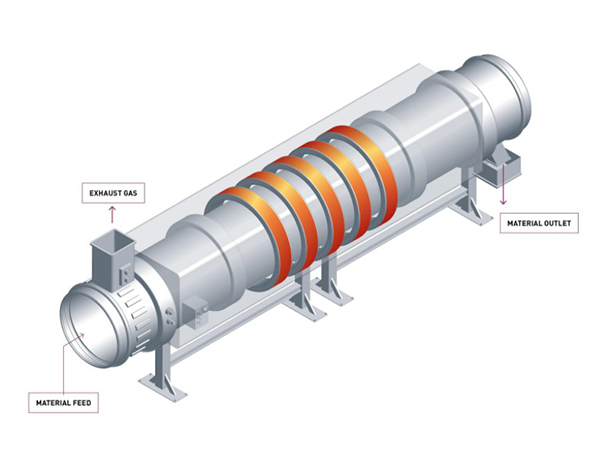

Alaabta waxaa lagu quudiyaa foornada in kastoo dhamaadka foornada (dhinaca sare ee dhululubada).Sababtoo ah dhululubada ayaa u janjeerta oo si tartiib ah u wareegta, alaabtu waxay la socotaa goobada iyo sidoo kale jihada axial (laga bilaabo dhinaca sare ilaa dhinaca hoose).Ka dib marka la maro isbeddel jidheed iyo kiimiko, walxuhu waxay galaan mashiinka qaboojinta iyada oo loo marayo daboolka madaxa ee foornada ka dib marka la dhammeeyo calcinta.Shidaalka waxaa lagu shubaa madaxa foornada iyada oo loo sii marayo madaxa foornada, gaaska qiiqa ayaa soo daadan doona dhammaadka foornada ka dib marka lagu beddelo kulaylka alaab.

Qiyaasaha Farsamada

| Qaabka | Halbeegyada Kiln | Awoodda (t/d) | Xawaaraha wareega (r/daqiiqo) | Awood (kW) | Miisaanka (t) | ||

| Dhexroor (m) | Dhererka (m) | Jilicsan(%) | |||||

| VS1.4x33 | 1.4 | 33 | 3 | 26 | 0.39-3.96 | 18.5 | 48 |

| VS1.6x36 | 1.6 | 36 | 4 | 37 | 0.26-2.63 | 22 | 52 |

| VS1.8x45 | 1.8 | 45 | 4 | 52 | 0.16-1.62 | 30 | 78 |

| VS1.9x39 | 1.9 | 39 | 4 | 56 | 0.29-2.93 | 30 | 78 |

| VS2.0x40 | 2 | 40 | 3 | 78 | 0.23-2.26 | 37 | 119 |

| VS2.2x45 | 2.2 | 45 | 3.5 | 106 | 0.21-2.44 | 45 | 128 |

| VS2.5x40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 150 |

| VS2.5x50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| VS2.5x54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| VS2.7x42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 199 |

| VS2.8x44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 202 |

| VS3.0x45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 211 |

| VS3.0x48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| VS3.0x60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| VS3.2x50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

| VS3.3x52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| VS3.5x54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

| VS3.6x70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| VS4.0x56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| VS4.0x60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| VS4.2x60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| VS4.3x60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| VS4.5x66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710 |

| VS4.7x74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

| VS4.8x74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |