I-Rotary Kiln yoMveliso weMveliso yeSamente

I-Rotary Kiln yoMveliso weMveliso yeSamente

Intshayelelo

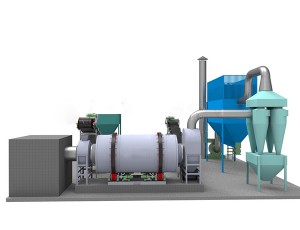

IKiln yesamente isetyenziswa ikakhulu ukwenza iclinker kwaye inodidi olomileyo kunye nohlobo olumanzi.

I-Metulrgical and kiln kiln yekhemikhali isetyenziswa ikakhulu kwi-iron ore ore magnetization calcination, i-oxidizing calcination ye-chromium ore, i-ferronickel ore;ukubalwa kwe-aluminium ephezulu ye-bauxite ore kwi-refractory material factory kunye ne-aluminium hydroxide, i-clinker, i-aluminium hydroxide calcination kwisityalo se-aluminium;ukubalwa kwe-chrome ore kunye ne-chrome powder kwisityalo sekhemikhali, njl.

I-kiln ye-lime esebenzayo isetyenziselwa ukubalwa kwekalika esebenzayo kunye ne-dolomite kumzi-mveliso wentsimbi kunye ne-iron alloy factory.

UmGaqo wokuSebenza

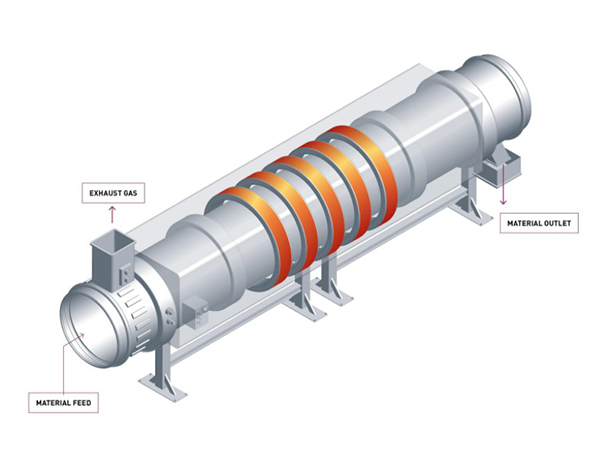

Izinto eziphathekayo zifakwa kwi-ontini nangona isiphelo se-kiln (icala eliphezulu le-cylinder).Ngenxa yokuba i-cylinder ithambekele kwaye ijikeleza ngokucothayo, izinto eziphathekayo zihamba kunye nesangqa kunye ne-axial direction (ukusuka kwicala eliphezulu ukuya kwicala elisezantsi).Emva kokutshintsha umzimba kunye neekhemikhali, izinto zingena kumatshini wokupholisa ngesigqubuthelo sentloko se-oven emva kokugqiba ukubala.I-fuel ifakwe kwintloko ye-oven ngentloko ye-oven, kwaye i-exhaust gas iya kuphuma ekupheleni kwe-oven emva kokutshintsha ubushushu ngezinto.

Iiparamitha zobuGcisa

| Umzekelo | Iiparamitha zeKiln | Umthamo(t/d) | Isantya sokujikeleza(r/min) | Amandla(kW) | Ubunzima(t) | ||

| Ububanzi (m) | Ubude(m) | Ukuthambeka(%) | |||||

| VS1.4x33 | 1.4 | 33 | 3 | 26 | 0.39-3.96 | 18.5 | 48 |

| VS1.6x36 | 1.6 | 36 | 4 | 37 | 0.26-2.63 | 22 | 52 |

| VS1.8x45 | 1.8 | 45 | 4 | 52 | 0.16-1.62 | 30 | 78 |

| VS1.9x39 | 1.9 | 39 | 4 | 56 | 0.29-2,93 | 30 | 78 |

| VS2.0x40 | 2 | 40 | 3 | 78 | 0.23-2.26 | 37 | 119 |

| VS2.2x45 | 2.2 | 45 | 3.5 | 106 | 0.21-2.44 | 45 | 128 |

| VS2.5x40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 150 |

| VS2.5x50 | 2.5 | 50 | 3 | 200 | 0.62-1,86 | 55 | 187 |

| VS2.5x54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| VS2.7x42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 199 |

| VS2.8x44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 202 |

| VS3.0x45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 211 |

| VS3.0x48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| VS3.0x60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| VS3.2x50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

| VS3.3x52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| VS3.5x54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

| VS3.6x70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| VS4.0x56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| VS4.0x60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| VS4.2x60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| VS4.3x60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| VS4.5x66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710 |

| VS4.7x74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

| VS4.8x74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |