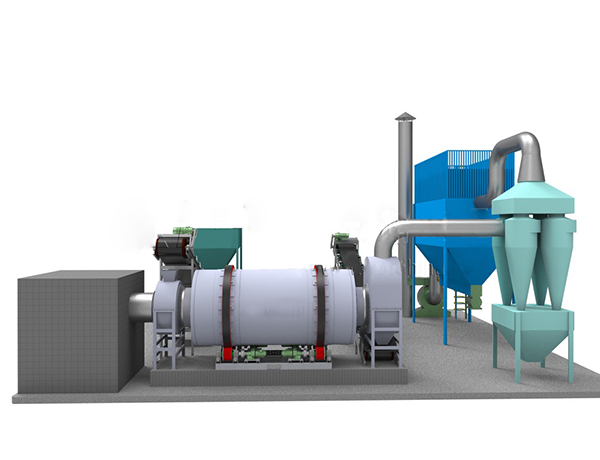

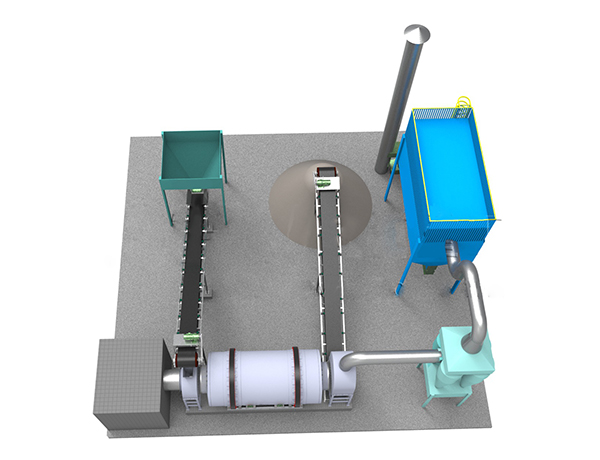

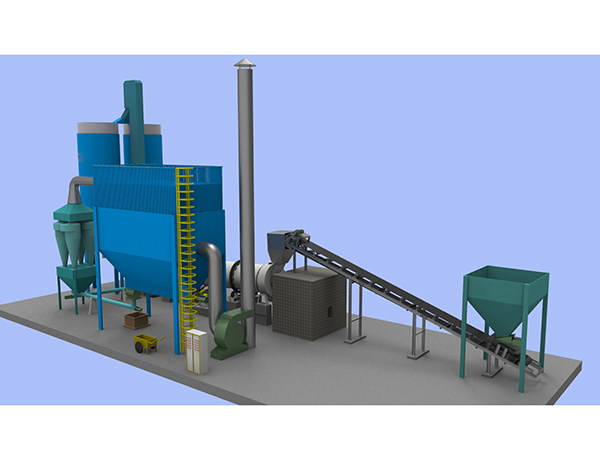

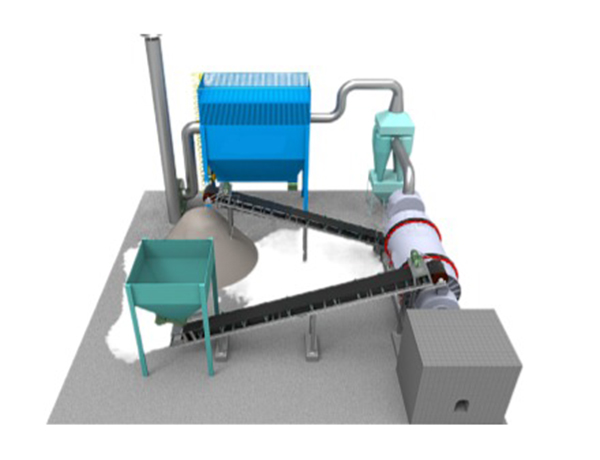

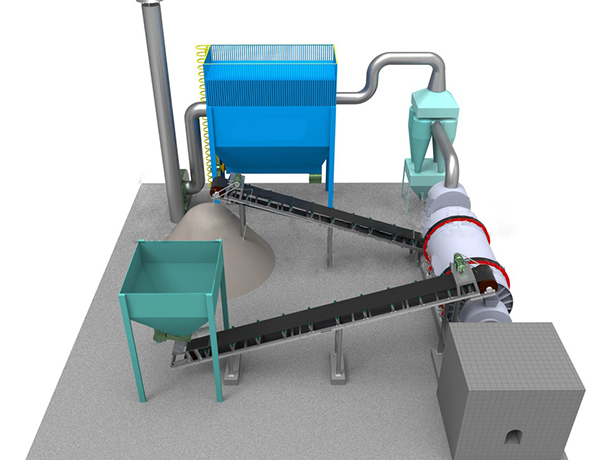

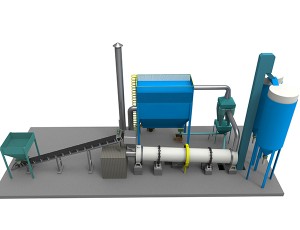

Tsarin bushewa na kayan ƙwararru

Tsarin bushewa na kayan ƙwararru

Amfanin Tsarin

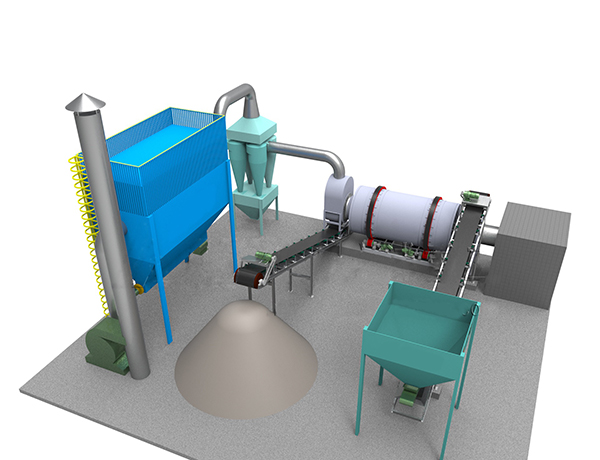

Babban ingancin thermal

Abun adana zafi tare da juriya mai zafi, haɗe tare da fasalin amfani da zafi na bushewar silinda uku, tasirin ceton makamashi a bayyane yake.

Ƙananan zuba jari na kayan aiki

Yanayin zafin jiki shine <50 ℃, wanda za'a iya shigar da shi kai tsaye cikin ɗakin ajiyar kayan, kuma ba a buƙatar na'urar sanyaya;Yanayin zafin wutsiya yana da ƙasa, kayan aikin cire ƙura yana tare da tsawon rayuwar sabis.

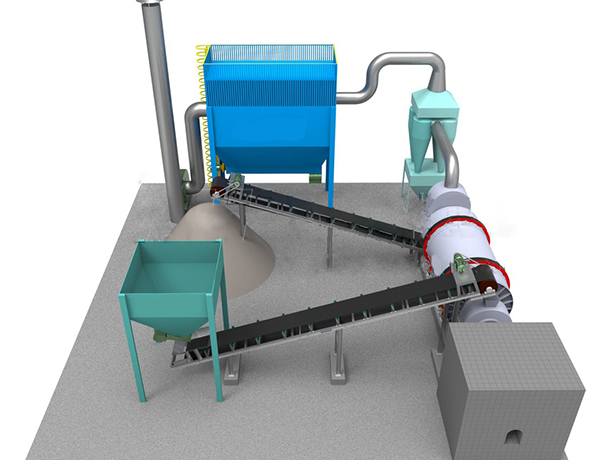

Ƙananan filin ƙasa, mai sauƙin shigarwa

Yankin da aka rufe shi ne 50% kasa da na na'urar busar da silinda guda ɗaya, zuba jarin gine-gine ya ragu da kashi 50% kuma an rage yawan amfani da wutar lantarki da kashi 60%, tsarin tsarin bushewa yana da ƙayyadaddun tsari mai sauƙi.

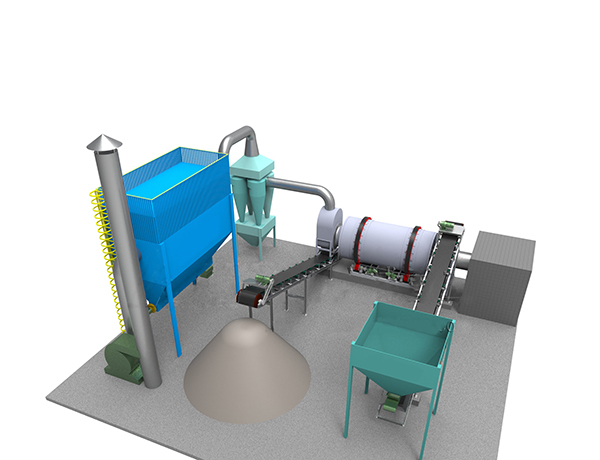

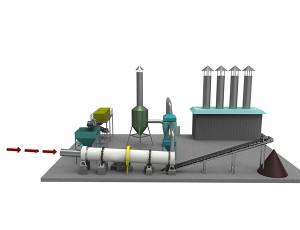

Ƙa'idar Aiki

Ana ciyar da kayan cikin kaskon ko da yake ƙarshen kiln (mafi girman gefen silinda).Saboda Silinda yana karkata kuma yana juyawa a hankali, abu yana motsawa tare da da'irar da kuma axial shugabanci (daga mafi girma gefe zuwa ƙananan gefe).Bayan yin canjin jiki da sinadarai, abu yana shiga cikin injin sanyaya ta cikin murfin kiln bayan gama calcination.Ana ciyar da man fetur a cikin kan kiln ta kan kiln, kuma iskar gas zai fita a ƙarshen kiln bayan musayar zafi da kayan.

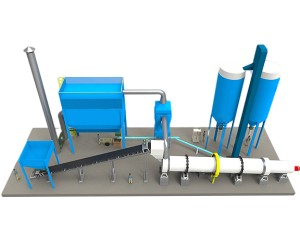

Ma'aunin Fasaha na Dryer Silinda Uku

| Samfura | Silinda bayanai | Iyawa (t/h) | Gudun juzu'i na Silinda (r/min) | Ƙarfi (kW) | ||||

| Silinda diamita na waje (m) | Tsawon Silinda na waje (m) | Girman Silinda (m3) | Kogin yashi | Tashi toka | Slag | |||

| VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2×4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3 ×2 |

| VS2×5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4 ×2 |

| VS2×6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7.5×2 |

| VS2.2×4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5.5×2 |

| VS2.5×6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5.5×4 |

| VS2.7×7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7.5×4 |

| VS2.8×6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5.5×4 |

| VS3×6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7.5×4 |

| VS3×7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7.5×4 |

| VS3.2×7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11×4 |

| VS3.2×8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11×4 |

| VS3.6×8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15×4 |

| VS3.8×9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15×4 |

| VS4×10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18.5×4 |

| VS4.2×8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18.5×4 |

Busassun Kayayyakin