Cindezela Isihlungi Esistakiwe se-VSPF

Cindezela Isihlungi Esistakiwe se-VSPF

Izici zezisetshenziswa

sebenzisa isakhiwo esistakiwe samapuleti, sebenzisa insiza yokuqondisa ukuze wenze umsebenzi uzinze kakhudlwana.

● Hlanganisa ukuhlunga, ukukhipha, ukuwasha, ukomisa umoya, ukuchithwa kwekhekhe nokugeza izindwangu ndawonye.

● I-extrusion pressure ifika ku-1.6MPa, isetshenziswa kabanzi ensimini enezidingo ezahlukene zomswakama wekhekhe.

● 4.sebenzisa isistimu yokulawula idrayivu ye-hydraulic, yenza umsebenzi uzinze futhi usebenzise amandla aphansi.

● Hlanganisa i-PLC, i-HMI kanye nesistimu yokulawula izinsimbi njll. kuhlakaniphe ndawonye, kwenza isihlungi sisebenze kahle futhi sibe lula.

● Sebenzisa umshini wokuhlanza amanzi anomfutho ophezulu ukuze wenze ukuwashwa kwendwangu kusebenze kangcono.

● Idizayini enegumbi eliyindilinga, isakhiwo esinengqondo ngokwengeziwe, ukusebenza kahle kugqame kakhulu.

Isimiso sokusebenza

I-1, Ukuhlunga: lapho iqembu lamapuleti livaliwe, futha i-slurry ukuhlunga, sebenzisa i-hose esabalalisiwe ukuze udle udaka ekamelweni ngalinye le-slurry, futhi ukuhlunga kudlule indwangu ukuze kuhlungwe uhlaka futhi kukhishwe, okuqinile kwakha ikhekhe phezu kwendwangu.

I-2, I-Extrusion: amanzi anengcindezi ephezulu afakwa ekamelweni eliphezulu le-diaphragm yenjoloba, yenza i-diaphragm ikhule futhi ikhiphe ikhekhe futhi uketshezi luzobe luphuma ekhekheni.

I-3, Ukugeza ikhekhe: ukugeza amanzi okuphakela ekamelweni elidaka ngokusebenzisa ikhava ye-hose esabalalisiwe phezu kwekhekhe ngokuphelele, ngaphansi kwengcindezi, amanzi okugeza adlula ikhekhe nendwangu ukuze akhiphe.

4, Ukomiswa komoya: umoya ocindezelwe ngokuphakelwa kwepayipi elisabalalisiwe ekamelweni elinodaka nokucindezela i-diaphragm yenjoloba, yenza amanzi anomfutho ophezulu ku-diaphragm yenjoloba aphume, futhi umoya ocindezelwe udlule ekhekhe futhi ukhiphe uketshezi ukuze unciphise umswakama wekhekhe izinga eliphansi kakhulu.

I-5, Ukukhishwa kwekhekhe: lapho usuqedile inqubo yokomisa umoya, vula iqembu lamapuleti, uhlelo lokushayela lwenza indwangu isebenze futhi ikhekhe liphume ezinhlangothini zombili zesihlungi ngesikhathi esifanayo.

Qaphela: Sicela ngokwesimo sangempela sokusebenzisa ukuze ulungise izikhathi ze-extrusion kanye nenqubo yokomisa umoya.

Umdwebo Wokugeleza Kwenqubo

Uchungechunge Lwezisetshenziswa

Ukucaciswa Kwezobuchwepheshe

| Imodeli/VI-SPFⅠ | VI-SPFⅠ-1 | VI-SPFⅠ-2 | VI-SPFⅠ-3 |

| Indawo yesihlungi/m2 | 1 | 2 | 3 |

| Usayizi wepuleti/mm | 0.5m2/ungqimba | ||

| Ipuleti qty/ungqimba | 2 | 4 | 6 |

| Ubude/m | 2.5 | ||

| Ububanzi/m | 1.5 | ||

| Ubude/m | 2 | 2.2 | 2.5 |

| Isisindo/T | 8 | 9 | 10 |

| Amandla wesiteshi seHydraulic/KW | 7.5 | ||

| Ikhanda lephampu yokukhipha/m | 167 | ||

| Iphampu ye-Extrusion flowrate m3/h | 8 | ||

| Amandla wepompo yokukhipha/KW | 7.5 | ||

I-Axiliary Equipment Data

| Inhloko yephampu yokugeza amapayipi/m | 70 | ||

| Iphampu yokugeza amapayipi igeleza m3/h | 10 | ||

| Ikhanda lephampu yokuwasha izindwangu/m | 70 | ||

| Iphampu yokuwasha izindwangu igeleza m3/h | 10 | ||

| Ikhanda lephampu lokuphakelayo eliludaka/m | 70 | ||

| Ipompo yokuphakela udaka igeleza m3/h | Ngokusho idatha slurry ukukhetha | ||

| Air drying pressure/Mpa | 0.8 | ||

| Ukugeleza kwe-compressor yomoya yokomisa umoya m3/min | 0.5 | 1 | 1.5 |

| Umthamo wethangi lokomisa umoya/m3 | 1 | 2 | 3 |

| Umfutho womoya wezinsimbi/Mpa | 0.7 | ||

| Ukugeleza kwe-compressor yomoya yezinsimbi m3/min | 0.3 | ||

| Izinsimbi umthamo wethangi lomoya/m3 | 0.5 | ||

| Phawula: ubukhulu bohlaka lwemishini ingusayizi oyisisekelo, kodwa akuwona usayizi wemininingwane, ngakho-ke lo sayizi ungowokubhekisela.Izinto ezihlukile zepuleti, isihlungi sizoba nobude obuhlukile nesisindo.Idatha yesisetshenziswa esiyisisetshenziswa njengereferensi nje, izoshintsha ngokusebenza kwesihlungi ngodaka oluhlukile. | |||

Ukucaciswa Kwezobuchwepheshe

| Imodeli | I-VSPFⅡ-3 | I-VSPFⅡ-6 | I-VSPFⅡ-9 | I-VSPFⅡ-12 | I-VSPFⅡ-15 | I-VSPFⅡ-18 | I-VSPFⅡ-21 | VSPFⅡ-24 |

| indawo yokuhlunga/m2 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| usayizi wepuleti/mm | 1.5m2/ungqimba | |||||||

| ipuleti Qty/ungqimba | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| ubude/m | 3.7 | |||||||

| ububanzi/m | 4.1 | |||||||

| ubude/m | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| isisindo/T | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| Amandla wesiteshi se-hydraulic/KW | 11 | |||||||

| Ikhanda lephampu yokukhipha/m | 28 | |||||||

| Ukugeleza kwephampu ye-Extrusion m3/h | 136 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingu-164 | |||||||

| Amandla wepompo yokukhipha/KW | 11 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingu-15 | |||||||

I-Axiliary Equipment Data

| Ikhanda lepompo lokugeza amapayipi /m | 68 | |||||||

| Iphampu yokugeza amapayipi igeleza m3/h | 20 | |||||||

| Ikhanda lephampu yokuwasha izindwangu/m | 70 | |||||||

| Iphampu yokuwasha izindwangu igeleza m3/h | 12 | |||||||

| Ikhanda lephampu lokuphakelayo eliludaka/m | 70 | |||||||

| Ukugeleza kwephampu yokuphakela udaka m3/h | Ngokusho idatha slurry ukukhetha | |||||||

| Air drying pressure/Mpa | 0.8 | |||||||

| I-air compressor flowrate yokomisa umoya m3/min | Ngokusho idatha slurry ukukhetha | |||||||

| Umthamo wethangi lokomisa umoya/m3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Umfutho womoya wezinsimbi/Mpa | 0.7 | |||||||

| Ukugeleza kwe-air compressor yezinsimbi m3/min | 0.5 | |||||||

| Izinsimbi umthamo wethangi lomoya/m3 | 1 | |||||||

| Phawula: ubukhulu bohlaka lwemishini ingusayizi oyisisekelo, kodwa akuwona usayizi wemininingwane, ngakho-ke lo sayizi ungowokubhekisela.Izinto ezihlukile zepuleti, isihlungi sizoba nobude obuhlukile nesisindo.Idatha yesisetshenziswa esiyisisetshenziswa njengereferensi nje, izoshintsha ngokusebenza kwesihlungi ngodaka oluhlukile. | ||||||||

Ukucaciswa Kwezobuchwepheshe

| Imodeli ye-VSPFⅢ | I-VSPFⅢ-18 | VSPFⅢ-24 | I-VSPFⅢ-30 | I-VSPFⅢ-36 | I-VSPFⅢ-42 | I-VSPFⅢ-48 | VSPFⅢ-54 | I-VSPFⅢ-60 | I-VSPFⅢ-66 |

| indawo yokuhlunga/m2 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| usayizi wepuleti/mm | 3.0m2/ungqimba | ||||||||

| ipuleti Qty/ungqimba | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| ubude/m | 5.1 | ||||||||

| ububanzi/m | 5.5 | ||||||||

| ubude/m | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| isisindo/T | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| i-hydraulic station powerKW | 22 | ||||||||

| Ikhanda lephampu yokukhipha/m | 40 | 55 | |||||||

| Ukugeleza kwephampu ye-Extrusion m3/h | 136 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingu-162 | 135 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingu-166 | |||||||

| Amandla wepompo yokukhipha/KW | 15 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingu-18.5 | 22 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingama-30 | |||||||

I-Axiliary Equipment Data

| Inhloko yephampu yokugeza amapayipi/m | 65 | ||||||||

| Iphampu yokugeza amapayipi igeleza m3/h | 26 | ||||||||

| Ikhanda lephampu yokuwasha izindwangu/m | 70 | ||||||||

| Iphampu yokuwasha izindwangu igeleza m3/h | 16 | ||||||||

| Ikhanda lephampu lokuphakelayo eliludaka/m | 70 | ||||||||

| Ipompo yokuphakela udaka igeleza m3/h | Ngokusho idatha slurry ukukhetha | ||||||||

| Air drying pressure/Mpa | 0.8 | ||||||||

| Ukugeleza kwe-compressor yomoya yokomisa umoya m3/min | Ngokusho idatha slurry ukukhetha | ||||||||

| Umthamo wethangi lokomisa umoya/m3 | 8 | 10 | 10 | 12 | 12 | 15 | 15 | 20 | 20 |

| Umfutho womoya wezinsimbi/Mpa | 0.7 | ||||||||

| Ukugeleza kwe-compressor yomoya yezinsimbi m3/min | 0.5 | ||||||||

| Izinsimbi umthamo wethangi lomoya/m3 | 1 | ||||||||

| Phawula: ubukhulu bohlaka lwemishini ingusayizi oyisisekelo, kodwa akuwona usayizi wemininingwane, ngakho-ke lo sayizi ungowokubhekisela.Izinto ezihlukile zepuleti, isihlungi sizoba nobude obuhlukile nesisindo.Idatha yesisetshenziswa esiyisisetshenziswa njengereferensi nje, izoshintsha ngokusebenza kwesihlungi ngodaka oluhlukile. | |||||||||

Ukucaciswa Kwezobuchwepheshe

| Imodeli ye-VSPFⅣ | I-VSPFⅣ-60 | I-VSPFⅣ-72 | I-VSPFⅣ-84 | I-VSPFⅣ-96 | VSPFⅣ-108 | I-VSPFⅣ-120 | I-VSPFⅣ-132 | I-VSPFⅣ-144 | VSPFⅣ-156 | I-VSPFⅣ-168 |

| Indawo yokuhlunga/m2 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| Usayizi wepuleti/mm | 6m2/ungqimba | |||||||||

| Ipuleti Ubuningi/ungqimba | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Ubude/m | 7.1 | |||||||||

| Ububanzi/m | 5.5 | |||||||||

| Ubude/m | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 | 8.3 | 8.6 |

| Isisindo/T | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

| Amandla wesiteshi seHydraulic/KW | 30 | 37 | ||||||||

| Ikhanda lephampu yokukhipha/m | 110 | 150 | ||||||||

| Ukugeleza kwephampu ye-Extrusion m3/h | 126 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingu-168 | 128 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingu-162.5 | ||||||||

| Amandla wepompo yokukhipha/KW | 37 Qaphela: uma ingcindezi ye-extrusion ingaphezu kuka-1.3MPa, le datha ingama-45 | 55 Qaphela: > 1.3MPa, le datha ingama-75 | ||||||||

I-Axiliary Equipment Data

| Inhloko yephampu yokugeza amapayipi/m | 72 | |||||||||

| Iphampu yokugeza amapayipi igeleza m3/h | 36 | |||||||||

| Ikhanda lephampu yokuwasha izindwangu/m | 70 | |||||||||

| Iphampu yokuwasha izindwangu igeleza m3/h | 20 | |||||||||

| Ikhanda lephampu lokuphakelayo eliludaka/m | 70 | |||||||||

| Ukugeleza kwephampu yokuphakela udaka m3/h | Ngokusho idatha slurry ukukhetha | |||||||||

| Air drying pressure/Mpa | 0.8 | |||||||||

| I-air compressor flowrate yokomisa umoya m3/min | Ngokusho idatha slurry ukukhetha | |||||||||

| Umthamo wethangi lokomisa umoya/m3 | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 45 | 45 |

| Umfutho womoya wezinsimbi/Mpa | 0.7 | |||||||||

| Ukugeleza kwe-air compressor yezinsimbi m3/min | 1 | |||||||||

| Izinsimbi umthamo wethangi lomoya/m3 | 2 | |||||||||

| Phawula: ubukhulu bohlaka lwemishini ingusayizi oyisisekelo, kodwa akuwona usayizi wemininingwane, ngakho-ke lo sayizi ungowokubhekisela.Izinto ezihlukile zepuleti, isihlungi sizoba nobude obuhlukile nesisindo.Idatha yesisetshenziswa esiyisisetshenziswa njengereferensi nje, izoshintsha ngokusebenza kwesihlungi ngodaka oluhlukile. | ||||||||||

Izinkambu Zokusebenza

Isetshenziswa kabanzi ekukhucululeni indle yasemadolobheni, ukuphrinta izindwangu nokudaya, i-electroplate, ukwenza iphepha, isikhumba, ukuphisa, ukucubungula ukudla, ukuwasha amalahle, imboni ye-petrochemical, i-chemistry, i-metallurgy, ukuhlukaniswa kwamaminerali, ikhemisi, imboni ye-ceramic sludge dewatering nokunye. ukukhiqizwa kwemboni ukuhlukaniswa koketshezi oluqinile noma inqubo ye-liquid leaching.

| Cha. | Igama lento | Ukuqina kokuphakelayo (g/l) | I-Extrusion water ressure (MPa) | Ukujiya kwekhekhe (mm) | Umswakama wekhekhe (%) | Umthamo kg/m2.h |

| 1 | 4A-zeolite | 150~295 | 1.4 | 35 | 19-22 | 190-200 |

| 2 | Isibabulethi | ≈50 | 1.2 | 30 | 30 | 120 |

| 3 | Ukuhola | ≈50 | 1.2 | 30 | 15-20 | 35 |

| 4 | I-copper slag | 600 | 1.6 | 40 | 8-9 | 310 |

| 5 | I-sulfate yamanzi angcolile | 80 | 1.6 | 45 | 28-35 | 120~175 |

| 6 | Calcination igolide tailings | 300 | 1.6 | 35 | 14-18 | 300 ~ 340 |

| 7 | I-Superfine aluminium hydroxide | 15~20% | 1.6 | 20 | 29.5–32 | 65 |

| 8 | I-Cu-Ni concentration | 66.7 | 1.6 | 30 | 9.78 | 257 |

| 9 | Ukugxila kwethusi | 45-50 | 1.6 | 35 | 7.6 | 360 |

| 10 | I-concentration | 45-50 | 1.6 | 30 | 8 | 300-400 |

| 11 | Iphunga le-Tantalum-niobium | 1.6 | 20~25 | 200 | ||

| 12 | I-slime yamalahle | 30~35% | 1.6 | 30 | 16-17 | 300 |

| 14 | Imisila yegolide ngemva kokuntanta | 20~30% | 1.6 | 35 | 12-18 | 300 |

| 15 | I-Mannitol | 1.5 | 12 | 35 | ||

| 16 | I-Zinc oxide powder | 57% | 1.6 | 18 | 20 | 90 |

| 17 | I-Leaching izinsalela ze-zinc oxide | 50% | 1.6 | 10 | 18~20 | 70 |

| 18 | Isibabule ukugxila | 10% | 1.6 | 20 | 25-35 | 200 |

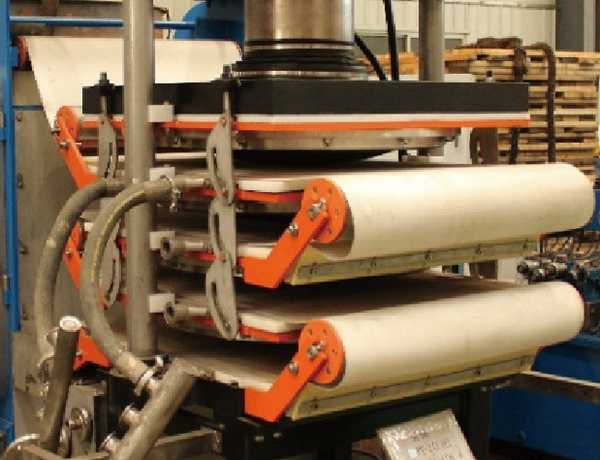

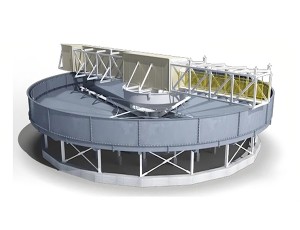

Isakhiwo Sezisetshenziswa

Isakhiwo Seqembu Lepuleti

Khiqiza Izithombe

Izingxenye Eziyinhloko

Ukusebenzisa Isayithi