Roller Crusher for Soft Material Crushing

Roller Crusher for Soft Material Crushing

Introduction

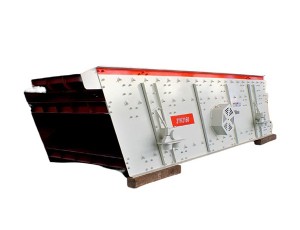

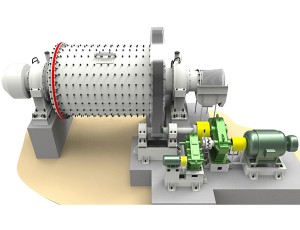

The rolls act as flywheels, contributing to smooth operation and efficient use of power. Roll crushing surfaces operate at a fixed distance apart, as opposed to the continually changing distances in a jaw or cone crusher. This creates a more consistent product size. Roll crushers are low in profile and relatively easy to install. They can be fed with a minimum of headroom, or even choke fed. Adjustments are simple and internal parts are readily accessible.

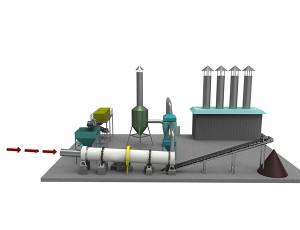

Applications for Roll Crusher

Typical feed materials for VOSTOSUN Roll Crushers include: bauxite, cement clinker, chalk, cinders, clay, coal, glass, gypsum, limestone, burnt lime, rock salt, sandstone, shale, sulfur ore, sea shells, and sewer sludge clinker. Single Roll Crushers, sometimes called lump breakers, can also be used for breaking frozen or agglomerated materials.

VOSTOSUN Roll Crushers are used in a variety of industries such as, mining recycling, and power industries. Interested in learning more about the VOSTOSUN Roll Crushers for your specific industry and application? Contact our sales engineers!

Main Technical Parameters of Roll Crusher

|

S,N |

Model |

Input size (mm) |

Output size (mm) |

Capacity (t/h) |

Power (kW) |

Weight (t) |

Protection Method |

|

1 |

2PG400×250 |

<12 |

0-5 |

5-13 |

2x5.5 |

1.1 |

Spring |

|

2 |

2PG450×500 |

<12 |

0-5 |

6-19 |

2x11 |

3.8 |

|

|

3 |

2PG600×750 |

<30 |

0-10 |

10-38 |

2x22 |

8.4 |

|

|

4 |

2PG610×400 |

<30 |

0-10 |

5-21 |

2x15 |

3.5 |

|

|

5 |

2PG800×600 |

<40 |

0-20 |

8-42 |

2x22 |

12.5 |

|

|

6 |

2PG900×900 |

<40 |

0-20 |

12-72 |

2x37 |

15.3 |

Spring/Hydraulic System |

|

7 |

2PG900×1200 |

<40 |

0-20 |

17-97 |

2x55 |

18.5 |

|

|

8 |

2PG1000×800 |

<50 |

0-30 |

12-75 |

2x45 |

21.6 |

|

|

9 |

2PG1200×800 |

<60 |

0-30 |

12-91 |

2x55 |

27.4 |

|

|

10 |

2PG1200×1200 |

<60 |

0-30 |

18-136 |

2x75 |

32.8 |

|

|

11 |

2PG1600×1200 |

<70 |

0-30 |

20-202 |

2x110 |

43.6 |

|

|

12 |

2PG1600×1600 |

<70 |

0-30 |

27-270 |

2x132 |

51.2 |

|

|

13 |

2PG1800×1600 |

<80 |

0-40 |

27-302 |

2x160 |

56.7 |